Positive Airflow Assemblies

Pressure Relief Manifold Assemblies

The Positive Air Flow (PAF) System™ is an engineering design that helps to reduce high resistance cable trouble in underground cables. The high resistance cable trouble is attributed to two primary factors: high ambient temperature and moisture in the underground. These factors can result in the development of high vapor pressure, which penetrates the cable sheath and results in elevated relative humidity readings in the cables. When a cable with high relative humidity (40% to 50%) comes in contact with a cooling force, such as a water main or creek, its temperature drops suddenly and the humidity condenses. This causes a moisture pocket to develop inside the cable which, in turn, causes the high resistance trouble.

The PAF System makes it possible to distribute a constant source of pressurized, monitored air flow through the cables. The increased air flow dries any existing or developing moisture pockets inside the sheath and helps to reduce/prevent high resistance cable trouble.

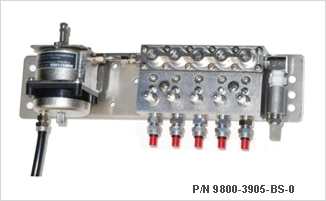

One of the important components in the system is the Pressure Relief Manifold Assembly. Two versions of the assembly are available—one for five cables (shown here) and one for ten cables (P/N 9800-3915-BS-0).

One of the important components in the system is the Pressure Relief Manifold Assembly. Two versions of the assembly are available—one for five cables (shown here) and one for ten cables (P/N 9800-3915-BS-0).

The 5-port manifold assembly consists of a stainless steel bracket containing a 0-30 psi High Resolution Pressure Transducer™, a five-port nickel-plated brass manifold, and a pressure relief valve. The 10-port manifold assembly (shown above) consists of a stainless steel bracket containing a 0-30 psi High Resolution Pressure Transducer™, two nickel-plated brass manifolds, and a pressure relief valve.

Unlike a standard manifold assembly, the Pressure Relief Manifold Assembly is not connected to an air pipe. Instead, the manifold ports connect directly to individual cables, allowing air to flow from the cables into the manifolds and out through the pressure relief valve. The pressure relief valve closes when pressure at the assembly drops to 4.85 psi, ensuring that adequate cable pressure is maintained.

For product specifications, refer to our data sheet.

As explained in the description above for the Pressure Relief Manifold Assembly, the Positive Air Flow (PAF) System™ is used in areas where exceptionally warm seasonal temperatures and sudden cooling can result in high resistance pair trouble in the underground (refer to our data sheet for an explanation). The Pressure Relief Transducer Assembly (Part No. 9800-3906-BS-0) is another PAF component that allows a small amount of air to flow out of a cable. This movement of air helps to prevent moisture pockets from developing, which ultimately cause the high resistance trouble.

The Pressure Relief Transducer Assembly consists of a stainless steel, 90-degree transducer mounting bracket that holds a 0-30 psi High Resolution Pressure Transducer™. Pneumatically connected to the transducer is a branch T with a 1/4" NPT-M to 3/8" tubing connector on one end (to accept feed from cable), and a pressure relief valve, manual shutoff valve and particulate filter on the other end.

The Pressure Relief Transducer Assembly consists of a stainless steel, 90-degree transducer mounting bracket that holds a 0-30 psi High Resolution Pressure Transducer™. Pneumatically connected to the transducer is a branch T with a 1/4" NPT-M to 3/8" tubing connector on one end (to accept feed from cable), and a pressure relief valve, manual shutoff valve and particulate filter on the other end.

Pressure Relief Manifold Assemblies

The Positive Air Flow (PAF) System™ is an engineering design that helps to reduce high resistance cable trouble in underground cables. The high resistance cable trouble is attributed to two primary factors: high ambient temperature and moisture in the underground. These factors can result in the development of high vapor pressure, which penetrates the cable sheath and results in elevated relative humidity readings in the cables. When a cable with high relative humidity (40% to 50%) comes in contact with a cooling force, such as a water main or creek, its temperature drops suddenly and the humidity condenses. This causes a moisture pocket to develop inside the cable which, in turn, causes the high resistance trouble.

The PAF System makes it possible to distribute a constant source of pressurized, monitored air flow through the cables. The increased air flow dries any existing or developing moisture pockets inside the sheath and helps to reduce/prevent high resistance cable trouble.

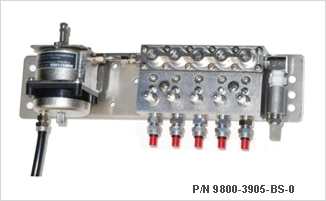

One of the important components in the system is the Pressure Relief Manifold Assembly. Two versions of the assembly are available—one for five cables (shown here) and one for ten cables (P/N 9800-3915-BS-0).

One of the important components in the system is the Pressure Relief Manifold Assembly. Two versions of the assembly are available—one for five cables (shown here) and one for ten cables (P/N 9800-3915-BS-0).The 5-port manifold assembly consists of a stainless steel bracket containing a 0-30 psi High Resolution Pressure Transducer™, a five-port nickel-plated brass manifold, and a pressure relief valve. The 10-port manifold assembly (shown above) consists of a stainless steel bracket containing a 0-30 psi High Resolution Pressure Transducer™, two nickel-plated brass manifolds, and a pressure relief valve.

Unlike a standard manifold assembly, the Pressure Relief Manifold Assembly is not connected to an air pipe. Instead, the manifold ports connect directly to individual cables, allowing air to flow from the cables into the manifolds and out through the pressure relief valve. The pressure relief valve closes when pressure at the assembly drops to 4.85 psi, ensuring that adequate cable pressure is maintained.

For product specifications, refer to our data sheet.

As explained in the description above for the Pressure Relief Manifold Assembly, the Positive Air Flow (PAF) System™ is used in areas where exceptionally warm seasonal temperatures and sudden cooling can result in high resistance pair trouble in the underground (refer to our data sheet for an explanation). The Pressure Relief Transducer Assembly (Part No. 9800-3906-BS-0) is another PAF component that allows a small amount of air to flow out of a cable. This movement of air helps to prevent moisture pockets from developing, which ultimately cause the high resistance trouble.

The Pressure Relief Transducer Assembly consists of a stainless steel, 90-degree transducer mounting bracket that holds a 0-30 psi High Resolution Pressure Transducer™. Pneumatically connected to the transducer is a branch T with a 1/4" NPT-M to 3/8" tubing connector on one end (to accept feed from cable), and a pressure relief valve, manual shutoff valve and particulate filter on the other end.

The Pressure Relief Transducer Assembly consists of a stainless steel, 90-degree transducer mounting bracket that holds a 0-30 psi High Resolution Pressure Transducer™. Pneumatically connected to the transducer is a branch T with a 1/4" NPT-M to 3/8" tubing connector on one end (to accept feed from cable), and a pressure relief valve, manual shutoff valve and particulate filter on the other end.